Why Superior Abrasives Live Up to Their Name in Industrial Grinding

- CTIS

- Jun 17, 2025

- 3 min read

Updated: Jun 27, 2025

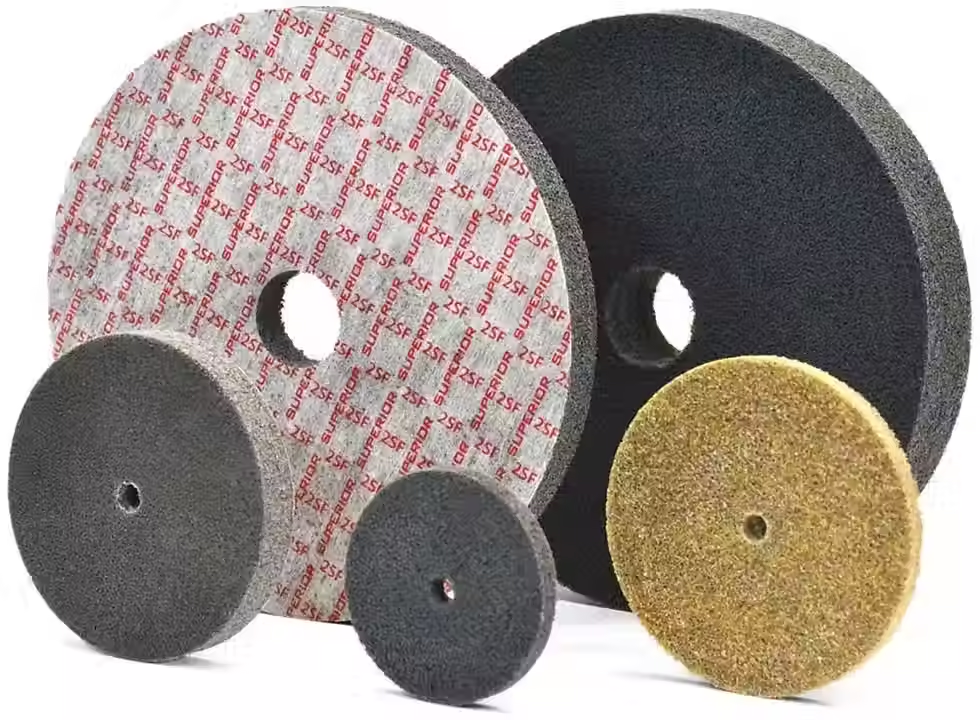

When it comes to metalworking, grinding is unforgiving. There's no room for subpar abrasives, especially when you're chasing surface finishes, tight tolerances, or efficient material removal. That’s why so many shops, from fabrication floors to aerospace machine rooms, turn to one brand in particular: Superior Abrasives.

The name isn’t marketing fluff—it’s a reflection of their performance. At CTIS, we see what gets results on the floor every day, and Superior delivers. From flap discs to resin fiber discs and belts, they offer industrial abrasives that perform under pressure, hold up longer, and grind smarter.

What Sets Superior Abrasives Apart?

Superior Abrasives doesn’t just sell product. They engineer solutions. Here’s what makes their abrasives a cut above:

1. Premium Grain Technology

Whether you're using ceramic, zirconia alumina, or aluminum oxide, Superior's grains are top-tier. Their ceramic grains, in particular, stay sharp longer and cut cooler—ideal for high-pressure applications and heat-sensitive metals.

Ceramic: Self-sharpening, best for stainless, titanium, and hardened steels

Zirconia Alumina: Tough and long-lasting, great for carbon steel and cast iron

Aluminum Oxide: Versatile and cost-effective for mild steel, aluminum, and softer metals

2. Consistent Wear and Longer Life

Superior Abrasives' bonding and backing systems are engineered for stability. That means less grit shedding, more controlled wear, and fewer disc changes during production.

Flap discs hold shape longer

Belts maintain pressure without glazing

Resin fiber discs grind steadily without sudden drop-off

3. Made for Metalworkers

These aren’t generic hardware-store abrasives. Every product in the Superior line is designed with industrial users in mind: welders, fabricators, machinists, and metal finishers who know the difference.

Standout Products in the Superior Abrasives Lineup

1. Flap Discs

Superior's flap discs are built for aggressive grinding with a consistent finish. Available in a wide range of grits and grain types, they’re ideal for:

Edge beveling

Weld blending

Deburring

Surface prep

Why shops love them: Long life, smooth operation, and less chatter on contoured parts.

2. Resin Fiber Discs

Need fast material removal? These discs offer high cut rates and durability, especially in heavy stock removal or coarse grinding on hard metals.

Best for: Steel plate, stainless tubing, structural steel, cast components

3. Abrasive Belts

From backstand grinding to robotic finishing, Superior belts offer:

Cool cutting action

Long belt life

Minimal loading on softer metals

Applications include: Pipe fabrication, tool polishing, heavy grinding on bar stock, and more.

Performance Across Metals

Abrasives that can't take the heat don’t last long in a real-world shop. Superior Abrasives are built to handle:

Stainless Steel: Ceramic flap discs reduce discoloration and heat buildup

Aluminum: Aluminum oxide belts resist loading and give smoother finishes

Carbon Steel: Zirconia resin fiber discs remove material fast and hold edge geometry

Tool Steels & Hard Alloys: High-pressure grinding with consistent grain exposure for finish-critical parts

No matter the job, Superior Abrasives help you finish faster and smarter.

The CTIS Advantage

Sourcing high-quality abrasives shouldn’t slow down your shop. CTIS not only stocks Superior Abrasives, we work with you to identify the best product for your metal type, machine setup, and grind pressure.

From belts to discs, we keep what you need moving — fast.

Need flap discs that can outlast the shift? Running into glazing issues with your current belts? Let’s fix that.

CTIS Proudly Supplies Superior Abrasives — Optimized for Your Toughest Grinding Jobs.

Contact us today to talk shop, request a sample, or place an order. We'll make sure you're grinding with the right tools — and not wasting time on the wrong ones.

Better abrasives. Fewer changeouts. Cleaner cuts.

Comments